Steam Turbine

This training course is split into three modules:

Course Outlines:

Turbine Types, Operation, Maintenance and Troubleshooting (API 611, 612 & 616).

- Course Introduction:

Steam turbines remain essential prime movers in the oil & gas, petrochemical, and power-generation industries. Their reliability, efficiency, and ability to operate under demanding process conditions make them a critical component of modern rotating equipment systems. This course provides a structured and practical introduction to steam turbine design, operation, and maintenance, with specific emphasis on the requirements of API Standard 611 and API Standard 612, the industry’s most widely recognized specifications for general-purpose and special-purpose steam turbines.

SteamTurbines

Participants will gain a comprehensive understanding of turbine fundamentals covering thermodynamic principles, mechanical design, lubrication systems, and auxiliary components. The course then builds on this foundation by exploring how API 611 and API 612 define performance expectations, safety considerations, construction features, allowable tolerances, inspection requirements, and documentation standards.

Special attention is given to differentiating between general-purpose turbines (API 611) commonly used in less severe service, and special-purpose turbines (API 612), designed for critical, continuous-duty applications with higher performance demands.

By the end of the course, participants will be able to confidently apply API standards to ensure reliability, efficiency, and long service life of turbine equipment in their facilities.

This training course is suitable to a wide range of QC Professionals but will greatly benefit:

1- Fresh Graduate Mechanical Engineers.

2- Operation, technical service and maintenance professionals.

3- Technical professionals responsible for maintenance and repair of steam turbines.

4- Professionals involved in inspection, maintenance and repair.

5- Technical professionals dealing with risk assessment and integrity analysis.

6- Technicians dealing with regulating and metering and other measurements of steam turbines.

Askyourself?

1): Do you enjoy troubleshooting construction equipment problems?

2): Are you familiar with the way rotating equipment should operate?

If the answer to these questions is yes, then a career as a Rotating Equipment Inspector could be right for you.

Rotating equipment inspectors: check and inspect pumps ,turbines, compressors, and similar rotating equipment used in the construction industry to ensure the equipment and/or equipment components are in good repairand meet construction project requirements.

In smaller organizations rotating equipment inspectors may also perform other tasks.

Course Outlines

Basics of Steam Turbine and Thermodynamics

1- Steam Thermodynamic features.

2- Steam Properties and the Mollier Charts.

3- Principle of Action.

4- Types of Steam Turbine.

5- Impulse Turbines.

6- Reaction Turbines.

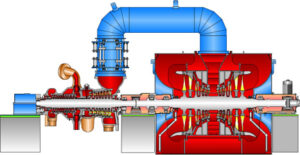

Steam Turbine Systems & Components

1- Steam Turbine Components.

2- Rotor Components.

3- Reaction and Impulse Blading.

4- Stator Blading.

5- Steam Turbine Bearings.

6- Lube Oil Systems.

7- Sealing Systems.

8- Governors and Control System.

Design, Selection and Sizing of Steam Turbine

1- Main Elements and Technical Characteristics of Steam Turbine Design.

2- Selection and Sizing of Steam Turbines for Compressor Drives.

3- Steam (Water) Rates.

4- Condensing and Backpressure Turbines.

5- Single and Multistage Types.

6- Process Considerations.

Operations of Steam Turbines

1- Commissioning.

2- Startup.

3- Run-In and Shut-down.

4- Surveillance and Health Monitoring.

5- Performance Measurement.

6- Monitoring and Tracking.

7- API 611 & 612.

Troubleshooting (Symptoms, Causes and Remedial Measures)

1- Construction Criteria for Steam Turbines.

2- Vibration Level and their Measurements.

3- Iso Standard 10816-2.

4- Bearing Housing Temperatures.

5- Accessories (Shaft seal, Bearing).

6- Troubleshooting and Failure Modes.

7- Shaft Alignment.

8- How to Correct Misalignment.

9- Soft Foot Definition.

10- Effects of Soft Foot.

11- Measuring Soft Foot.

12- Correcting Soft Foot.

Preventive and Predictive Maintenance

1- Maintenance by Plan Vs. Maintenance by Default.

2- Equipment Reliability and Availability.

3- Building and Maintenance Management Plan.

4- Energy Saving Opportunities for Steam Turbines.

هل الدورة اونلاين ؟

نعم ، الدبلومة اونلاين عبر zoom meeting من خلال الشرح الاونلاين التفاعلي وايضا تحصل علي التسجيلات ويمكنك الاحتفاظ بها .

هل يمكنني الحصول علي مديول واحد فقط ؟

نعم ، يمكنك الحصول علي مديول واحد فقط لأن الدبلومة مقسمة الي ثلاثة مديول كل مديول بمثابة كورس منفصل بشهادة منفصلة .

هل احصل علي شهادة بعد اتمام دراسة الدبلومة ؟

نعم ، يمكنك الحصول علي شهادة لكل مديول ، الشهادة معتمدة من الاكاديمية وموثقة علي موقع الاكاديمية .

هل هذا الكورس مؤهل لشهادة دولية ؟

الدبلومة يتم فيها تناول الجانب المعرفي والعملي كما هو مذكور في محتوي الدبلومة ، ايضا الدبلومة تساعدك علي فهم الاكواد العاليمة (API) المؤهلة لأمتحان API SIER الدولي.

هل يمكنني الحصول علي الماتريل وتسجيلات المحاضرات ؟

نعم ، يمكنك الحصول علي تسجيلات المحاضرات واحدث نسخة من الاكواد المستخدمة وكذلك المادة العلمية.

هل الدورة مناسبة لحديثي التخرج ايضا ؟

نعم ، الدبلومة مناسبة جدا لحديث التخرج وايضا الرغبين في الدخول الي هذا المجال ، لانها تبدأ معاك من الصفر وحتي الاحتراف ، وذلك لانك ينقل لك خلاصة الخبرة العلمية والعملية من خلال المدرب والمادة العلمية .