Corrosion inspection, Monitoring and Corrosion Control in Petroleum Applications

Course Introduction:

This course covers a basic but thorough review of Corrosion Integrity Management. Active participation is encouraged through hands-on experiments, case studies, and open discussion format.

This Corrosion Management course covers fundamental AMPP course of Corrosion Integrity Management The course will enable attendees to establish a solid foundation in corrosion before moving on to advanced topics. Exercises, hands-on practical sessions and virtual experiments throughout the course will help participants understand the basic concepts and fundamentals important to corrosion. This course also helps participants to optimize the efficiency of production facilities also, the course will define the used chemicals for operations, recognize terms and definitions of basic electrochemistry, as well as differentiate between inspection and monitoring and identify the common testing techniques for each.

It provides an excellent avenue for corrosion practitioners, designers, technical managers, inspection and maintenance engineers, quality control personnel and those involved in failure analysis to update their appreciation of corrosion and the awareness of the emerging technologies for corrosion control and prevention.

Course Objectives:

Upon completion of this course the participants will be well known for the following items:

• Expected the corrosion forms and failure mechanisms.

• Identify the appropriate methods for determining corrosion rates in production line by different monitoring techniques.

• Identify the appropriate methods of protection against corrosion.

• How to choose the appropriate chemicals to protect against corrosion.

• How to determine appropriate does of corrosion inhibitors to maintain production facilities.

• Determining the fitness for service by inspection techniques (NDT).

• Pigging and smart pigging.

• Welding defects and the resulted mechanism of corrosion failure.

• Management of chemical injection and tips for extra protection.

• Tests of corrosion lab and how it will be useful for production. [Process Plant Optimization by corrosion control and enhancement of integrity level]

• Material Selection

• Improved design to control

• Coating process and inspection

• Cathodic protection

• Integrity Verification/Assessment

Who Should Attend?

This course is designed for engineers, chemists and technicians, other professionals who

would like to expand their knowledge of Corrosion control, monitoring and management.

Course Outlines:

Module 1

Introduction to Basic Corrosion

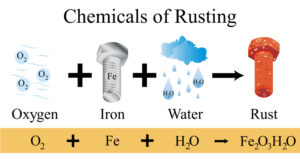

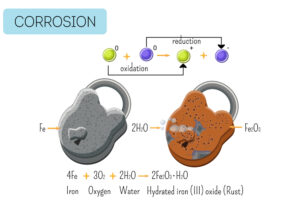

1.1. Definitions of corrosion.

1.2. The threats and impacts of internal corrosion in the oil and gas

1.3. Basics of corrosion.

1.4. Different forms of internal corrosion

· Uniform Corrosion

· Localized Corrosion

· Pitting

· Crevice Corrosion

· Mesa Corrosion

· Weld Zone Corrosion

· Environmentally Assisted Cracking (EAC)

· Flow-Assisted Damage

1.5. Diagnosis of failure cases resulted from corrosion

1.6. Why do metal corrodes?

· Metals Extraction and alloys manufacturing.

· Factors affecting corrosion.

· Electrochemical nature of corrosion.

· Kinetics of corrosion cells.

1.7. Corrosion definitions.

1.8. Corrosion process Reactions:

· Initiation of anodic sites.

· Cathodic Reactions

1.9. Erosion -Corrosion process

1.10. Practical corrosion cases from fields and detailed illustration for each case.

1.11. Exercise/practical session

1.12. Microbiologically influenced corrosion and its treatment

1.13. How to measure the corrosion rate by different techniques.

1.14. Manifold and Gathering corrosion data

· Production manifolds

· Flow line characteristics

· Gathering systems

· Flow of fluids

1.15. Oil and Water Treatment (Scale inhibition)

· Oil treatment

· Water treatment

Module 2

2.1. The Corrosive Species, their effects on internal corrosion and Mechanisms for:

· Carbon Dioxide (CO2)

· Hydrogen Sulfide (H2S)

· Oxygen

· Microbiologically Influenced Corrosion

2.2. Effects on CO2 Corrosion

2.3. Corrosion Modeling for CO2 Corrosion

2.4. Analysis of gases by chromatography and other devices to get suitable doses

2.5. Factors Involved in the Corrosion of Oilfield Steel

2.6. Failures from Hydrogen Damage to Oilfield Steels

2.7. Types of Cracking

· SCC (Stress Corrosion Cracking)

· HIC (Hydrogen Induced Cracking)

· HE (Hydrogen Embrittlement)

· SSC (Sulfide Stress Cracking)

· CSC (Chloride Stress Cracking)

· Corrosion Fatigue

2.8. Corrosion Management

· Optimization of Internal Corrosion management Program

· Risk management

· Risk identification

2.9. Corrosion Control by Materials Selection

· Effect of dissolved gases

· Effect of dissolved salts

· Stream Velocity

· Process Flow Diagram (PFD) and Material selection Guide (MSG)

- Material selection according to the related operations and temperatures.

· Metallic piping and connection [Advantages and limitations]

· Non-Metallic piping and connection [Advantages and limitations]

· Fiber Glass piping and connection [Advantages and limitations]

· Material Costs and Availability

2.10. Pilling – Bedworth ratio.

2.11. Galvanization.

2.12. Exercise/practical session

Module 3

3.1. Corrosion Control by Improved Design:

- Advantages of appropriate engineering design

- Welding Defects

- Corrosion Allowance

- Flange Isolating Kits

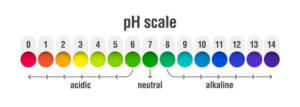

- Corrosion Control by Chemical Treatment:

- pH Control

- Removal of Dissolved Gases Mechanically.

Module 4

4.1. Lab Testing

- Efficiency of inhibitors :

- Corrosion Inhibitor Performance Evaluation

- Wheel Box Test (HP/LP)

- Kettle (Bubble) Test

- Rotating Cylinder Electrode (RCE)

- Flow Loop

4.2. What is Corrosion Monitoring?

4.3. Corrosion measurement techniques including:

(Non Destructive Testing Analytical Chemistry, Operational Data Fluid Electrochemistry, Potentiodynamic measurements, A.C. impedance, Corrosion Monitoring).

4.4. The Need for Corrosion Monitoring.

4.5. Corrosion Monitoring Techniques.

4.6. Advantages of Corrosion Monitoring

4.7. Corrosion Coupons (Weight Loss).

4.8. Electrical Resistance (ER) Monitoring.

4.9. Galvanic Monitoring.

4.10. Specialized Monitoring.

4.11. Applications of Corrosion Monitoring Techniques.

4.12. Field Monitoring

- Coupons

- Probes (ER/LPR)

- Iron Count

- UT Measurement

- Rapid-charging/boost

4.13. Inspection for pipelines and different facilities

- On-Line Wall Thickness measurement by Ultrasonic Testing ( UT )

- Dye Penetrant Testing ( PT )

- Magnetic Testing ( MT )

Module 5:

5.1. Revision for failure mechanisms

5.2. Exercise/practical session

5.3. Protective Coating (Painting Works)

- Technical & Inspection Requirements

- Painting Systems.

- Surface preparation:

- Dry Sand Blasting

- Wet Abrasive Blast Cleaning

- Power Tool Cleaning

- Method of Work (Blasting & Painting).

- Paint application.

Module 6:

6.1. Pigging operations

- Mechanism of pigging.

- Conditions of successful pigging.

- Types of pigs.

- Material selection for pigs.

6.2. Introduction to Pigging Technology

- How pigs work

- Pig functions and selection

- Pipeline design for pigging

- Pigging techniques

6.3. Pigging for Pipeline Integrity Assessment

- The needs for pigging

- Overview of pipeline internal inspection and monitoring methods and capabilities

- Advanced ILI technologies: what methods are available for the pipeline industry?

- Capabilities and functions of ILI tools: what can they do?

6.4. What Pipeline Operators Need to Know About Pigging:

- Type of pigs available

- How intelligent pigs work

- Piggable vs unpiggable pipelines

- Impact of pigging inspection on the operation of pipelines

- When to use intelligent pigs

- Budgeting for ILI inspection

- Reliability of intelligent pigs

6.5. Cathodic Protection

- System Sacrificial anode system

- Impressed current system

- Cathodic protection monitoring

- CP System Design

- Electrical Isolation

- Sacrificial VS Impressed Current CP

Module 7:

(Chemical Control)

7.1. Process Management

7.2. Chemical Control of Corrosion

7.4. Chemical Cleaning of closed systems

7.5. Desludging the tanks and separators:

- Used Procedures

- Used Chemicals

- How to treat the sludge and investigate the sludge analysis

7.4. Study Cases and Tips

7.5. Technical assessment

Module 8:

(Corrosion Inhibitor)

10.1 The threats and impacts of internal corrosion in the oil and gas

10.2 Corrosion Modeling for CO2 Corrosion

10.3 Corrosion inhibitor:

- Theory of inhibition.

- Mechanism of inhibition.

iii. Types of inhibitor.

- How to measure the inhibition efficiency of the applied inhibitor.

- Filming

- Stability of inhibitors

vii. Batch vs. Continuous Injection

viii. Formulation factors to consider

10.4 Lab Testing

- Efficiency of inhibitors :

- Corrosion Inhibitor Performance Evaluation

- Wheel Box Test (HP/LP)

- Kettle (Bubble) Test

- Rotating Cylinder Electrode (RCE)

- Flow Loop

10.5 What is Corrosion Monitoring?

10.6 Corrosion measurement techniques including:

(Non Destructive Testing Analytical Chemistry, Operational Data Fluid Electrochemistry, Potentiodynamic measurements, A.C. impedance, Corrosion Monitoring).

Module 9:

(Scales)

11.1 What is Scale and Why does it form

• Definition

• Problems caused

• Formation

• Types of scale

• Scale prediction

• Scale inhibition

• Product selection

11.2 Predicting scale formation

11.3 Controlling scale formation

11.4 Program monitoring

• Laboratory tests for selection

• Treatment methods

• Scale squeeze design

• Case study – wax / horizontal wells

• Case study – wax / chalk formation

• DepCon

• Case Study – ACCESS

• Case Study – CAPEX

Module 10:

(Biocides)

12.1 Microbial Influenced Corrosion

12.2 Microorganisms types

12.3 Bacteria classification

12.4 Components of a typical bacterium

12.5 SRB Corrosion

12.6 Forms of SRB

12.7 The Requirements for SRB Growth

12.8 SRB Corrosion Mechanism – Electrochemical Reactions

12.9 Effect of SRB & Biofilm Presence

12.10 Treatment & Control of SRB

12.11 Ideal Biocide Characteristics

12.12 Biocide Mode of Action

Module 11:

(Scavengers)

13.1 Ionization of H2S in water

13.2 Aldehyde Treatments

13.3 Sulphide Scavenger Chemistry

13.4 Methods of H2S removal.

13.5 Removal Methods for Oxygen

13.6 Parameters Affect on Oxygen Scavenging

Course Methodology:

A variety of methodologies will be used during the course that includes:

- (30%) Based on Case Studies

- (30%) Techniques

- (30%) Role Play

- (10%) Concepts

- Pre-test and Post-test

- Variety of Learning Methods

- Lectures

- Case Studies and Self Questionaires

- Group Work

- Discussion

- Presentation

الأسئلة الشائعة

هل الدورة اونلاين ؟

نعم ، الدورة اونلاين عبر

zoom meeting

من خلال الشرح الاونلاين التفاعلي وايضا تحصل علي التسجيلات ويمكنك الاحتفاظ بها .

هل احصل علي شهادة بعد اتمام دراسة الكورس ؟

نعم ، يمكنك الحصول علي شهادة بعد اتمام دراسة الكورس ، الشهادة معتمدة من الاكاديمية وموثقة علي موقع الاكاديمية .

هل هذا الكورس مؤهل لشهادة دولية ؟

الدبلومة يتم فيها تناول الجانب المعرفي والعملي كما هو مذكور في محتوي الدبلومة ، ايضا الدبلومة تعتبر مدخل الي عالم التآكل حيث يمكنك بعد اتام دراسة هذه الدبلومة الدخول الي المرحلة التخصصية في عالم التآكل.

هل يمكنني الحصول علي الماتريل وتسجيلات المحاضرات ؟

نعم ، يمكنك الحصول علي تسجيلات المحاضرات واحدث نسخة من الاكواد المستخدمة وكذلك المادة العلمية.

هل الدورة مناسبة لحديثي التخرج ايضا ؟

نعم ، الكورس مناسبة جدا لحديث التخرج وايضا الرغبين في الدخول الي هذا المجال ، لانها تبدأ معاك من الصفر وحتي الاحتراف ، وذلك لانك ينقل لك خلاصة الخبرة العلمية والعملية من خلال المدرب والمادة العلمية .