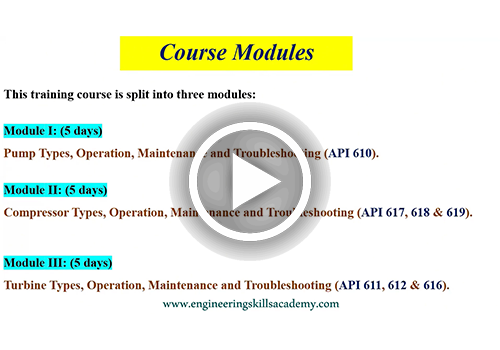

This training course is split into three modules: Module I:

Pump Types, Operation, Maintenance and Troubleshooting (API 610). Module II:

Compressor Types, Operation, Maintenance and Troubleshooting (API 617, 618 & 619). Module III:

Turbine Types, Operation, Maintenance and Troubleshooting (API 611, 612 & 616).

Module I: Pump Types, Operation, Maintenance and Troubleshooting (API 610).

Classification, Types of Pumps and Compressors

➢ Pump Types, Positive Displacement and Dynamic.

➢ Operating characteristics.

➢ Centrifugal Pumps.

➢ Priming, Cavitation.

➢ NPSHA, NPSHR.

➢ Power requirements for pumping.

➢ Pump curves and Pump Selection.

✓ Head capacity curve (H-Q).

✓ Efficiency capacity curve.

➢ Specific Speeds.

➢ Operating point of centrifugal pump.

➢ Pumping system optimization.

Operation and Troubleshooting

➢ Startup, Priming, Shut down.

➢ Vibration level and their measurements.

➢ Bearing housing temperatures.

➢ Accessories (Shaft seal, Bearing).

➢ API 610.

Troubleshooting (Symptoms, Causes and Remedial Measures)

➢ The function of bearing in rotating machine.

➢ Shaft alignment.

➢ How to correct Misalignment.

➢ Soft foot definition.

➢ Effects of soft foot.

➢ Measuring soft foot.

➢ Correcting soft foot.

Preventive and Predictive Maintenance

➢ Maintenance by plan Vs. Maintenance by default.

➢ Equipment reliability and availability.

➢ Building and maintenance management plan.

➢ Energy saving opportunities for pumps.

Module II: Compressor Types, Operation, Maintenance and Troubleshooting (API 617, 618 & 619).

Compressors Working Principles, Types, Operational Aspects

➢ Classification, Types of compressors.

➢ Operational principles and constructional feathers.

➢ Compressor operation.

➢ Performance characteristics curve.

Compressors Operational Aspects, Selection and Specification Criteria

➢ Minimum and maximum flow constraints.

➢ Surge, significance and control.

➢ Compressor selection and specification criteria for drive rating selection.

➢ Performance testing.

➢ Standards and acceptance criteria for performance testing.

Operation, Troubleshooting and API Standards

➢ Startup, Priming, Shut down.

➢ Vibration level and their measurements.

➢ Bearing housing temperatures.

➢ Accessories (Shaft seal, Bearing).

➢ API 617 (Centrifugal Compressors).

➢ API 618 (Reciprocating Compressors).

➢ API 619 (Positive Displacement Compressors).

Troubleshooting (Symptoms, Causes and Remedial Measures)

➢ Surge and Stonewall on Compressors.

➢ Shaft alignment.

➢ How to correct Misalignment.

➢ Soft foot definition.

➢ Effects of soft foot.

➢ Measuring soft foot.

➢ Correcting soft foot.

Preventive and Predictive Maintenance

➢ Maintenance by plan Vs. Maintenance by default.

➢ Equipment reliability and availability.

➢ Building and maintenance management plan.

➢ Energy saving opportunities for Compressors.

➢ Steam Thermodynamic features.

➢ Steam Properties and the Mollier Charts.

➢ Principle of Action.

➢ Types of Turbine.

➢ Impulse Turbines.

➢ Reaction Turbines.

➢ Configuration Variants, Application Ranges & Constraints.

➢ Steam and Gas Turbines Components.

➢ Rotor Components.

➢ Reaction and Impulse Blading.

➢ Stator Blading.

➢ Steam and Gas Turbine Bearings.

➢ Sealing Systems.

➢ Governors and Control System.

➢ Main Elements and Technical Characteristics of Steam and Gas Turbines Design.

➢ Selection and Sizing of Steam and Gas Turbines for Compressor Drives.

➢ Steam (Water) Rates.

➢ Condensing and Backpressure Turbines.

➢ Single and Multistage Types.

➢ Process Considerations.

➢ Operations of Steam Turbines

✓ Commissioning.

✓ Startup.

✓ Run-In and Shut-down.

✓ Surveillance and Health Monitoring.

✓ Performance Measurement.

✓ Monitoring and Tracking.

✓ API 611 & 612.

➢ Operations of Gas Turbines

✓ Commissioning.

✓ Startup.

✓ Run-In and Shut-down.

✓ Surveillance and Health Monitoring.

✓ Performance Measurement.

✓ Monitoring and Tracking.

✓ API 616.

DAY 15:

➢ Machine Overhaul Process.

➢ Machines Piping and Ground Regulations.

➢ Alignment of Thermal Machines.

➢ Balancing of Rotating Machines.

➢ Surface Treatments of Sealing Interfaces.

➢ Online/Offline Washing.

➢ Troubleshooting through Vibration Analysis.

➢ Oil Analysis and Thermography.

هل الدورة اونلاين ؟

نعم ، الدبلومة اونلاين عبر zoom meeting من خلال الشرح الاونلاين التفاعلي وايضا تحصل علي التسجيلات ويمكنك الاحتفاظ بها .

هل يمكنني الحصول علي مديول واحد فقط ؟

نعم ، يمكنك الحصول علي مديول واحد فقط لأن الدبلومة مقسمة الي ثلاثة مديول كل مديول بمثابة كورس منفصل بشهادة منفصلة .

هل احصل علي شهادة بعد اتمام دراسة الدبلومة ؟

نعم ، يمكنك الحصول علي شهادة لكل مديول ، الشهادة معتمدة من الاكاديمية وموثقة علي موقع الاكاديمية .

هل هذا الكورس مؤهل لشهادة دولية ؟

الدبلومة يتم فيها تناول الجانب المعرفي والعملي كما هو مذكور في محتوي الدبلومة ، ايضا الدبلومة تساعدك علي فهم الاكواد العاليمة (API) المؤهلة لأمتحان API SIER الدولي.

هل يمكنني الحصول علي الماتريل وتسجيلات المحاضرات ؟

نعم ، يمكنك الحصول علي تسجيلات المحاضرات واحدث نسخة من الاكواد المستخدمة وكذلك المادة العلمية.

هل الدورة مناسبة لحديثي التخرج ايضا ؟

نعم ، الدبلومة مناسبة جدا لحديث التخرج وايضا الرغبين في الدخول الي هذا المجال ، لانها تبدأ معاك من الصفر وحتي الاحتراف ، وذلك لانك ينقل لك خلاصة الخبرة العلمية والعملية من خلال المدرب والمادة العلمية .